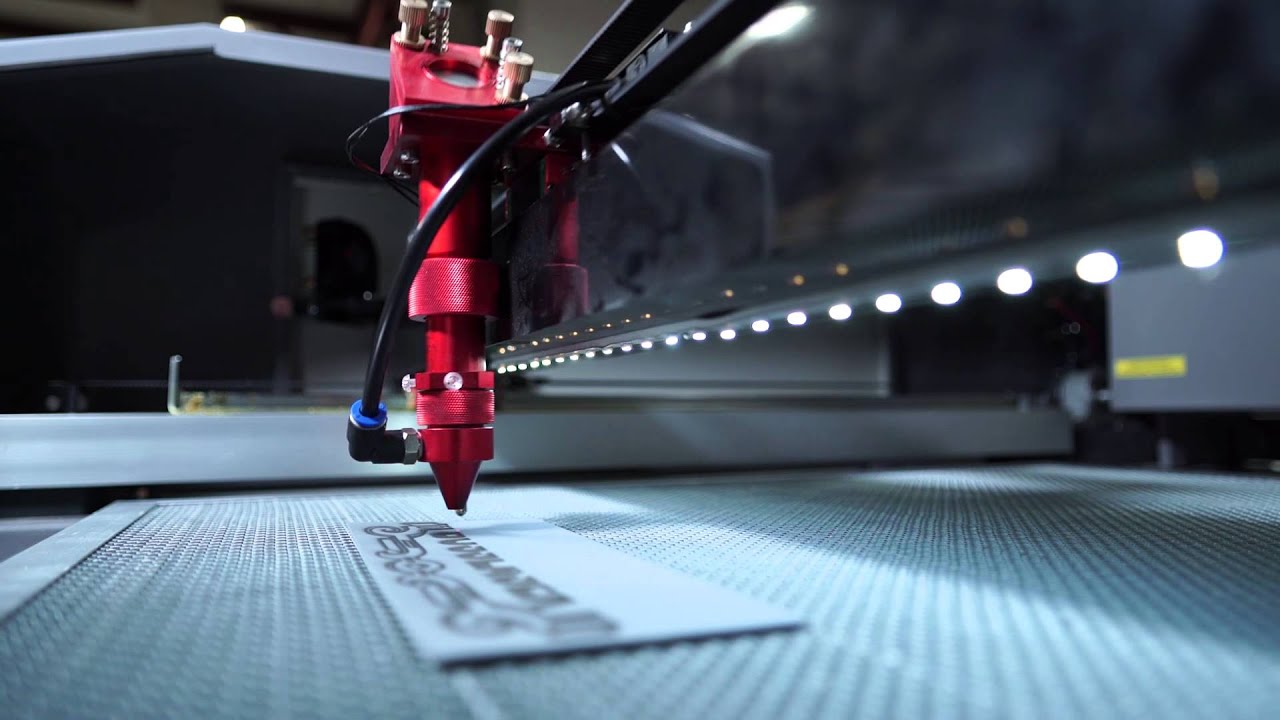

Laser marking is the process of customizing specific items and protecting intellectual property mostly used by businesses around the globe. In a fiber laser cutter, a laser beam physically removes a surface layer of material to expose a cavity to form a shape that can be either letters, logos, or a combination of both.

The main advantage of using laser marking is that it gives a higher level of safety measures and reveals an image the eye can view so that the product can be seen separately from the rest of the products of the same type in the market. For businesses, it also helps in providing customer security as the original products can be instantaneously identified.

How is the laser marking done?

In the case of fiber lasers, laser generation begins by pumping intense diode light into the end of fiber optic cables. The end of the cables has also been doped with a rare element known as ytterbium.

The energy from the diode light is absorbed by ytterbium in the fiber optic cables and then released in the form of photons. The high energy photons then travel down the optic cables, which creates the laser beam of wavelength around 1062 nm. The process is quick, and most laser engraving machines work with almost any kind of metal and many engineered plastics.

As there are hundreds of companies producing the same product with thousands of different names, it is quite difficult for the original companies to maintain their identity. It is because, among the thousands of the same products, a lot are frauds and are not even worth one-tenth of the price the consumer will be paying for. And because of these frauds, renowned companies earn a bad name as most of these frauds look like the top-selling products from the established firms. In the production sector, laser marking stands for identification in the forms of texts, logos, or both in many cases.

Apart from that, laser marking is also ideal for credit cards, ID cards, sensitive documents, and other items that provide additional safety measures. In ID cards, multilayer formats are used to alter the color of the lower layer’s pigments. It gives the benefit of altering the color, without affecting the top transparent layer, which ensures security, produces high-quality images and text, and makes it tamper-proof and customizable.

What are the advantages of laser marking?

Here are some of the common advantages of using laser marking:

- It ensures that no identification theft of the original product is done in the production sector.

- Laser engraving enables the firms to store important information such as serial numbers, time stamps, barcode etching, branding, and industry-specific codes on customizable surfaces.

- It has enabled easy transaction and management, paving the way for barcode scanners, RFID scanners, or other inventory tracking tools.

- Even in diverse domains such as in robotics, 3D printing, banking, government agencies, and the automotive sector, laser marking is making things easier.

Conclusion:

As technology is pacing at a tremendous pace, both theft and privacy need to be taken care of. And laser marking is a method that contributes positively in both the sectors. Whether an additional layer of security is needed to prevent fraud or duplication of intellectual property, laser marking will always come to your use. Apart from that, terms such as time-saving and job efficiency have received new heights after the invention of laser marking, making tracking and maintenance an easy job.